OUR Ultrasonic ANTI Fouling Technology

-THE ULTRASONIC SOLUTION-

Ultrasound has been used in industry for decades; sterilization in medical sector, welding for plastics, cleaning of parts in industry, algal control solution in food production and many many more.

Through the use of targeted ultrasonic transducers it is possible to provide acoustic sonication to generate non-inertial cavitation bubbles at a low amplitude providing a scrubbing / cleaning effect and a sterilization / disruption effect to the growth of micro-organisms and algae within the immediate vicinity of the structures being protected.

This technological adaption and advancement allows us to bring bio fouling prevention to the marine sector without any introduction of toxin, heavy metals, biocides or similar. Essentially utilizing acoustic energy to achieve the results. Read on below to learn more.

ULTRASONIC PRESSURE IS KEY

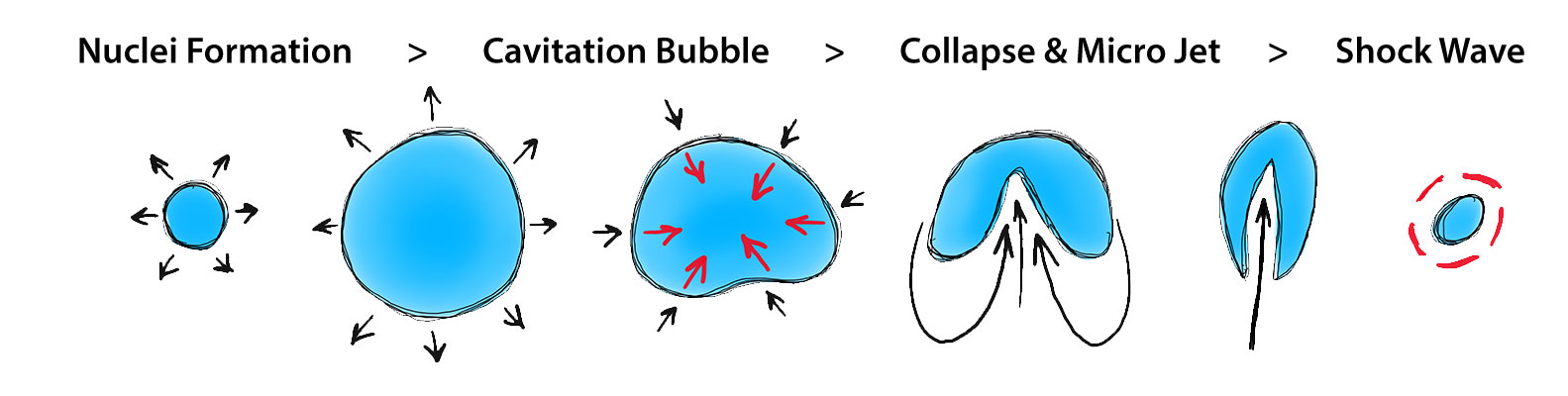

Ultrasonic energy is emitted into the structure / surface of the material at carefully targeted frequencies and power levels. This ultrasonic acoustic energy produces a series of pressure variations, high (compression) & low (rarefaction), within the liquid that in turn form microscopic non-inertial cavitation “bubbles” on or near to the surface or impurities within the fluid where they can nucleate. The process of generating and destroying these “bubbles”, at various targeted sizes (frequencies), produces both an agitation of the surface area for the cleaning effect and damage to the cell wall of microscopic algae/bacteria where the non-inertial cavitation occurs on or near to the impurities.

How It works?

CleanAHull works by producing a series of targeted bursts of ultrasonic energy called acoustic sonication.

These bursts of energy are transmitted via our CleanAHull ultrasonic transducers, installed in strategic locations onto the structures to be protected.

The result is ultrasonic energy generating microscopic bubbles that provide the protection within the water column.

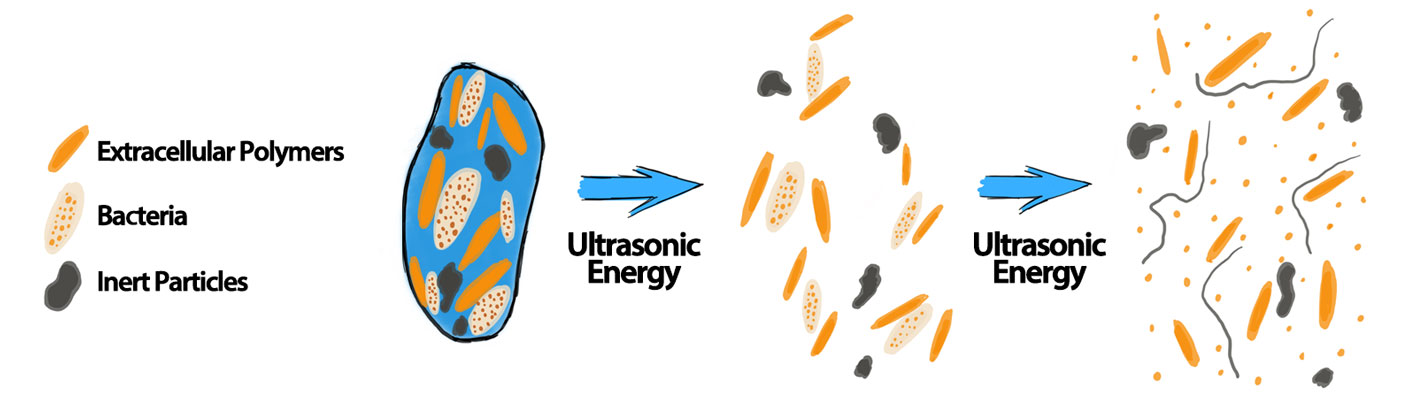

ULTRASONIC ACOUSTIC DISINTEGRATION OF ALGAE & BACTERIA

The diagram below shows the effects of ultrasonic acoustic energy on algae and bacteria. The ultrasonic cavitation causes disintegration of the cell wall of algae and bacteria reducing the same to inert particles and preventing continued colonization or growth.